I’ve been playing around with the “808” keychain video camera. This is a tiny digital video recorder that captures very good quality video, yet sells for less than $15, shipped! (Try eBay.) That includes an internal LiIon battery, recharged via the USB port, but not the microSD card you need to buy separately. (My hat is off to the Chinese manufacturers – how they can do it at that price I don’t know.)

Quite a few of the flyers in the local CMASS rocket club have been attaching these to model rockets (using high-tech attachment methods like masking tape or velcro) to get in-flight videos.

Chuck Lohr’s wonderful site at http://www.chucklohr.com/808/ is the place for technical information on this thing – this posting is my little contribution to the cause.

I’ve been working on installing mine (a so-called #3 type – see Chuck Lohr’s page) in the electronics bay of my GPS-steered rocket recovery system, to take videos of the parachute deploying and being steered in flight (plus, it’s cool).

Since a high-power rocket will sometimes sit on the launch pad for 30-60 minutes before flight, I need a way to turn it on with my on-board microcontroller at launch time.

This technique should work with any microcontroller that runs on 3.3 volts (the same voltage as the logic in the camera). The specifics apply to the #3 type camera, but the general idea will probably work with the others as well.

If you open up the #3 (carefully, avoid stripping or cracking the delicate plastic screw holes), the side of the board with the buttons looks like this:

I’ve marked four positions on the board, you want to solder wires onto these:

- The right side of the capacitor near the left end of the board. This can be used to monitor whether the camera is turned on. When there is 3.3v on this cap, the camera is turned on. When there’s 0v (ground), it’s off. Connect this to an input line on your microcontroller.

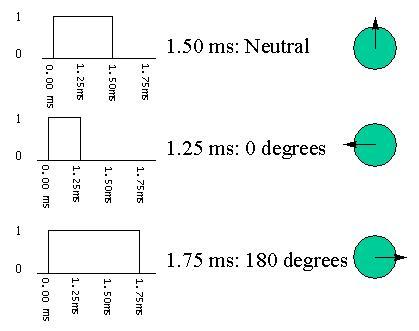

- The lower right connection on the power button. This controls when the power button is pressed; connect it to an output. Driving this pad low (0v) presses the power button, driving it to 3.3v releases it.

- The upper right connection on the mode button. This controls when the mode button is pressed. The voltages on it are the opposite of the power button: 3.3v presses the button, 0v releases it.

- Note there’s a place at the top right of the board for another SMD LED. I soldered a green one there to see what it would do – it lights up when the board is connected to a live USB port.

- Last, you’ll need a ground connection. I found the best place to be any one of the four tabs that attach the USB connector (on the other side of the board, not shown). Just add a blob of solder and attach the ground wire.

[Update 2011-07: Since I wrote this posting, I got a 2nd “#3” camera on eBay. This one appears identical externally and functionally, but internally has a newer PCB. Driving it is identical, except that the mode button has opposite polarity – 0v is closed, 3.3v is open. YMMV.]

Once you’ve got at least the 3 minimum wires connected up (power button, mode button, and ground), operating the camera is a simple matter of software.

To take a movie on the #3 camera (others may vary), press the power button for 1.3 seconds to turn on the camera. Then release it and wait 4.5 seconds. Then press the mode button for 3.0 seconds. The camera will start recording a movie.

To stop it, just turn off the camera by pressing the power button for 1.3 seconds again. [Update 2011-07: A better way is to press the mode button for 200 mS.]

These times are the minimum values I found would work reliably. Note that if you wait more than about 40 seconds between pressing the power button and the mode button, the camera will turn itself off, and you’ll have to start over.

Here’s my modified 808, ready to connect up to the microcontroller – I can still press the buttons with a little screwdriver.

Update, September 2013:

Lately I’ve had a few people ask me for the source code I use to drive the camera, so here it is: videoCam.zip.

It’s pretty self-explanatory, but the idea is that you call InitVideo() once to initialize it, then call ManageVideo() periodically (at least every 100 mS or so) to manage the camera. The global “Video” tells it if you want to be recording or not.

It’s implemented as a simple finite-state machine.

Post any questions here; I’ll try to answer.